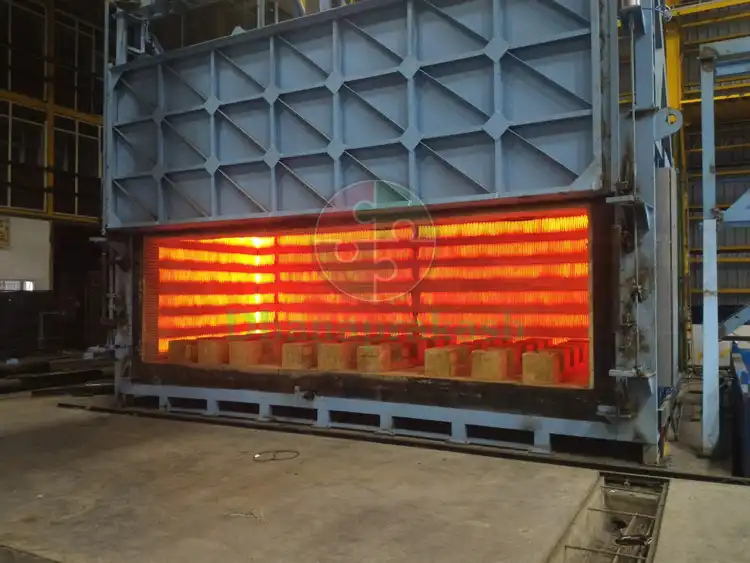

Heat Treatment Furnaces

Latest, Strong, Sturdy, PLC/PC Controlled Heating Quenching Technology by Dhanaprakash MN Steel Hardening, SS Solution treatment, Forging, Quenching, Tempering & Normalising. Also available for PWHT (Post Weld Heat Treatment) (N+Q+T & Q+T)

Applications

- Annealing

- Normalising

- Hardening

- Solution Treatment Heating

- Forge Heating

- Tempering

- Aluminium Solutionising

- Stress Relieving

- Ductile Iron Full Annealing

- ADI (Austempered Ductile Iron).

Auto cycle control

- Ramp, Soak, Cool .... 8 Steps Profile

- 10, 20 Profile Memory

- Multi Input Multi Output (MIMO)

- PID Controlling Action.

- PLC Based programmable controller.

- One burner, one thermocouple forms one pair as zone, thus multi zone control

- Digital display for time temperature graph online with USB pen drive for data storage, Wired LAN PC connectivity for real time graph printing

- Complete Report generation by data logging & Processing (SCADA).

Firing

- High Velocity Short Flame Burner.

- Direct On/Off pulse firing effect.

- Smokeless perfect combustion.

Uniformity

- Calibrated to API, AMS, CQ9, STM, ASME, NORSOK

- National Traceability (NABL)

The furnaces are calibrated for uniformity as per API 6A Standard (The Temperature Difference Between Highest & Lowest Points at Stabilised Conditions should not be more than 13ºC.)

Mechanization

- Trolley - movement by geared motor with brake.

- Door - movement by geared motor with brake, counter weighed,

- Door Lock Unlock - innovative, pneumatically operated instant latching unlatching for perfect sealing.

Construction

- Strong rigid construction.

- Heat resistant grade CI castings at door and frame, bogie and furnace interface eliminates warpage.

- Railway rails for load bearing under temperature.

- Triple sealing minimising heat losses.

Insulation

- High temperature high density ceramic fibre Monolithic Anchored lining.

- Self-supporting Monolithic Anchored Extended door lining.

Recuperator

- All fuel fired furnaces are equipped with Recuperator to recover the heat from flue gases by preheating combustion air. By thumb rule a rise of 1500 C in combustion air 7.5% heat is recovered.

PLC control

- Large furnaces handle high value materials; it is essential to install PLC for operation to avoid manual errors.

- PLC checks each & every operation prior to loading of materials called booting to ensure air/gas/power etc. are within the specifications & all the sensors are in working condition

- PLC monitors each & every operation during auto cycle for supply conditions, flue temperatures burner operations any deviation is automatically notified audio visually & through SCADA.

- PLC keeps event history for the record.

Control Panel

- Aesthetically powder coated control panel.

- Electrical switch gears for drives, burners.

- Status indication and control.

- Burner sequence controller and flame failure device.

- Programmable start-up, burner, temperature controlling system.

#Annealing Furnaces #Drop Quench Furnaces #Heat Treatment Furnaces

Downnload Brochures

- Heat Treatment Furnaces

- Rapid Quench

- Submersible Agitator for Rapid Quench

- Burner

- Automation

- Foundry Industry

- Heat Treatment Rotary Hearth Furnace

Heat Treatment Furnaces - videos

10 MT Hardening Furnace - 15 MT Tempering Furnace - Rapid Quench Heat Treatment

5 MT Rapid Quench Diesel Fired Heat Treatment Furnace At Saudi Arabia

Automated Hardening Rapid Quenching Plant(N+Q+T)

Rotary Hearth Retort Type Hardening Tempering Plant

Solution treatment Quenching in 30 seconds

50 Ton Quenching in 65 seconds

Rapid Quench Bogie Hearth Furnace

Hardening Quenching Tempering Normalising With XYZ Manipulator

Rapid Quenching System - Hardening Solution treatment, Overhead XY Manipulator

Heat Treatment Furnace - Hardening Quenching With XYZ Manipulator

Retort Type Hardening Furnace

Automated Drop Quench Heat treatment furnace for Aluminium

Rapid Quenching System - Hardening Furnace with XYZ Manipulator

Heat Treatment Furnace - Hardening Quenching With XYZ Manipulator

15 MT Hardening and Rapid Quenching with XYZ Manipulator

+91- 7767 005 678

+91- 7767 005 678