Infrastructure

Area - 105000 Sq. Ft, 55000 Built up Total 3 Units

Power - 65 HP MSEB | Uninterrupted Power supply at Each Units

Design & Drawing

- Burners of all types: - Design, Pilot testing, Manufacturing of Gas, Oil Burners.

- Designing of Furnaces, Ladle Preheaters, Mould.

- Driers, Core driers, Incinerators, Pollution control Equipments.

- Structural and Thermal designing of related components.

- Designing of Thermal Profiles.

- Designing of Electrical Circuitry.

- Developing required programs for PLC and integrating the same into automation system.

- 3D modelling, Simulation, etc. are the routine steps of our Production

- Concepts are illustrated by animations.

Pilot Plant

- R&D facilities with a dedicated technical team, and commitment to ongoing R&D for new product development and improvement in existing products.

- Test laboratory facility for carrying out pre/post product analysis for waste disposal, calcining, drying, or any other process that requires heating.

- After sales support facilities for all products

Testing Facility

- Muffle Furnace.

- Thermocouple Calibration Furnace.

- Oil Fired Test Oven for Testing Products Directly.

- Aluminium Melting Test Furnace.

- High Temperature Box Furnace.

- Oil Gas Burner Testing Set-Up.

- Air Flow, Pressure, Velocity Testing Set-Up.

- Complete manufacturing set up with trained, and experienced manpower.

Manufacturing Facilities

Workshops

Full-fledged 4 Nos workshop having CO2 and Arc welding, Plasma cutting Machine, shearing, power hex saw, grinder, machining with tools tackles, guages and trained manpower.

STORAGE FACILITY

Training

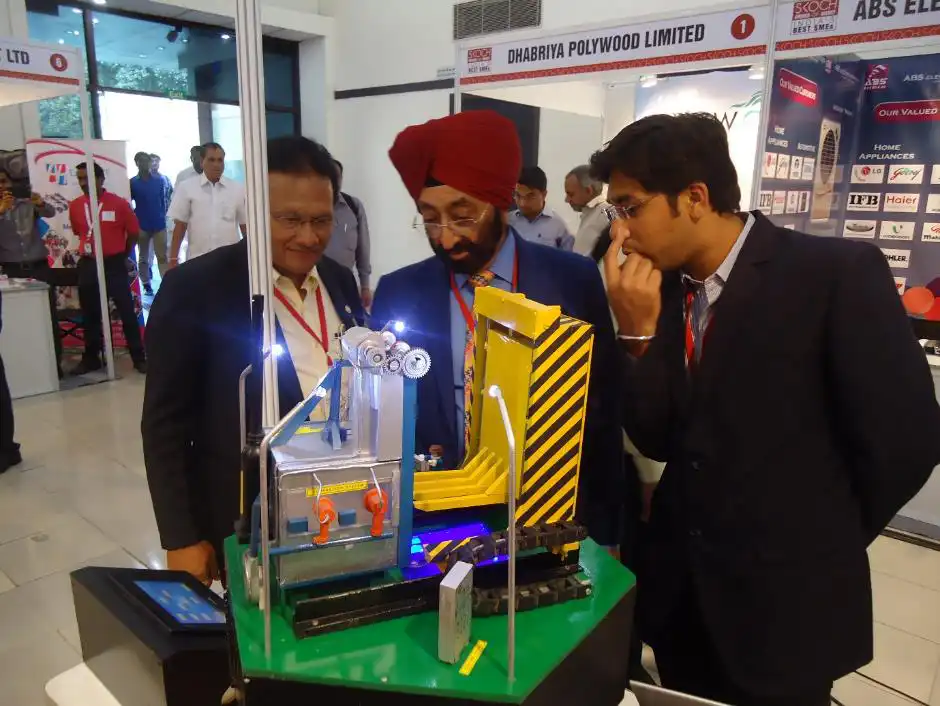

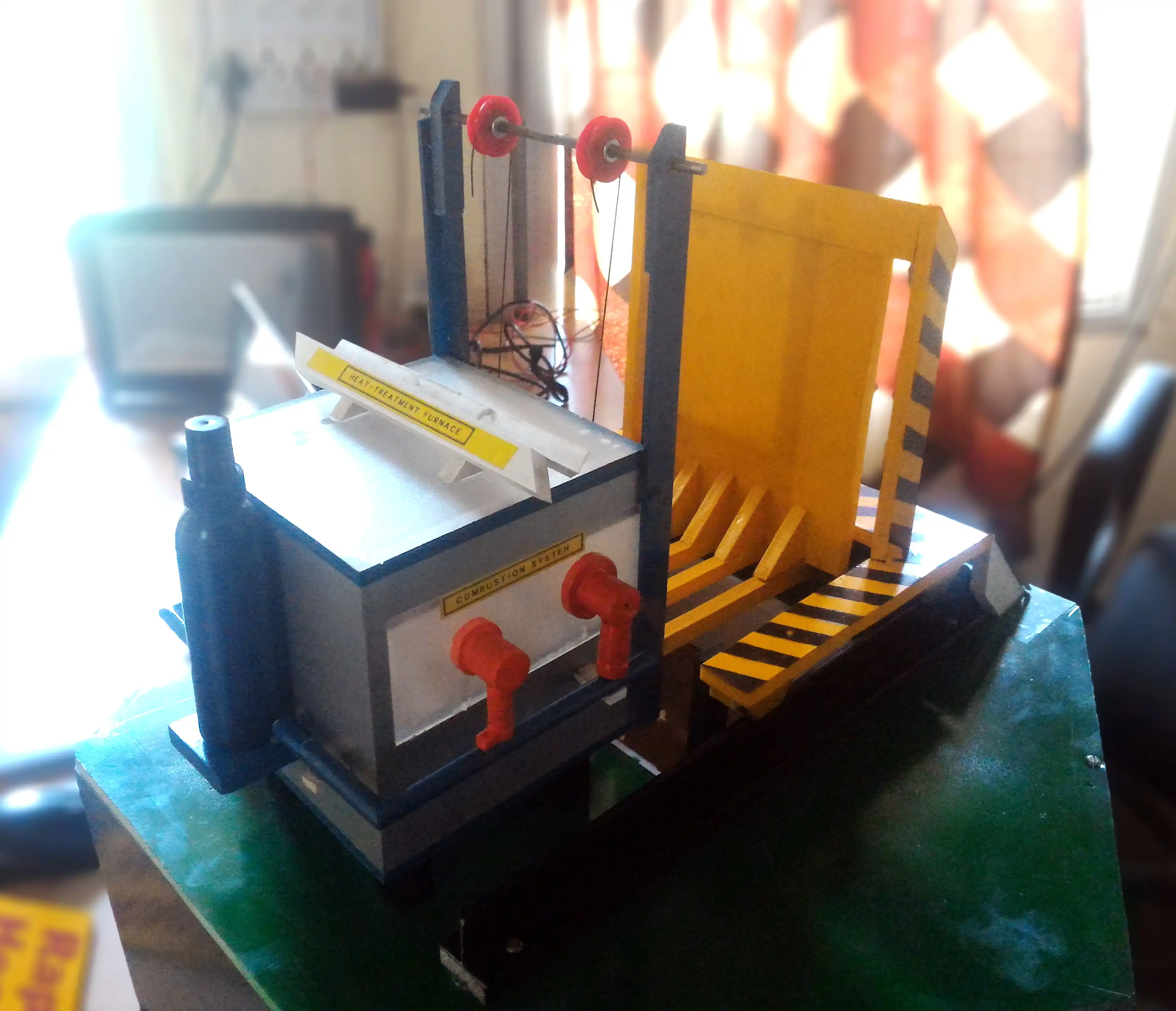

At Dhanaprakash, we create a miniature model for the demonstration purpose which helps our clients to get better ideas how their Furnaces Manufactured at Dhanaprakash works.

Miniature model of Heat Treatment Furnaces for Demonstration

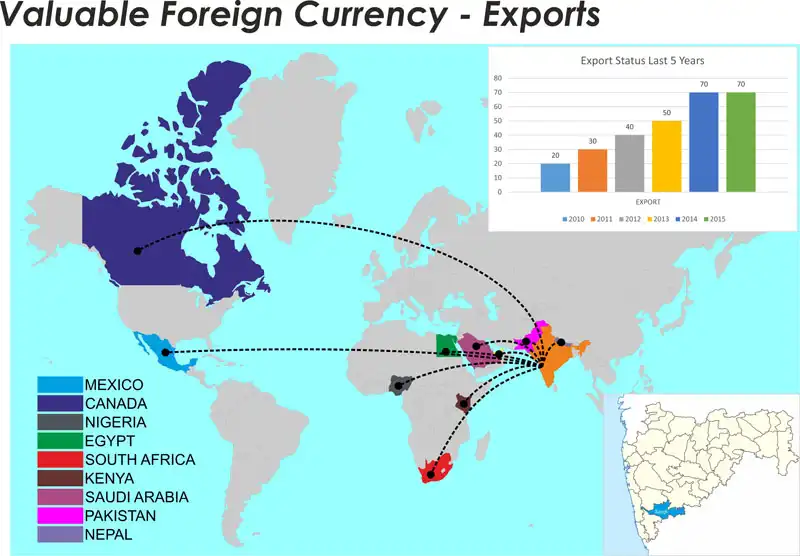

Export

We are exporting our Furnaces to Mexico, Nigeria, South Africa, Pakistan, Nepal, Saudi Arabia, Canada, Egypt, Kenya etc.

Association

- National Centre for Technical Services, Pune.(www.iifncts.org)

- Institute of Indian Foundrymen (www.indianfoundry.com )

- International Flame Research Foundation, Netherland.(www.ifrf.net)

- Central Mechanical Engineering Research Institute, Durgapur. www.cmeri.net

- Network of Indian Environmental Professionals. www.envindia.com

- Mitcon Consultancy Services Ltd, Pune. www.mitcnindia.com

- India Lead Zinc Association, Delhi

- Tata Energy Research Institute, New Delhi. www.teri.org

- Indo Swiss Vocational Training Trust. www.isvtt.org

- Krishna Valley Chambers of Industries & Commerce

- Laghu Udyog Bharati. www.lubindia.org

Channel Partner

- Murgappa Morgon Thermal Ceramic Ltd. - Soft Ceramic Products

- Murgappa Morgon Thermal Ceramic Ltd. - Soft Ceramic Products - ACE Caldryes Ltd. - Castables, Mortors

- ACE Caldryes Ltd. - Castables, Mortors

Publication

- Foundry Journal

- Indian Foundry Journal.

- Energy & Fuel User's Journal.

- Vichar Bharati's Special Issue on Entrepreneurship.

- India Lead Zinc Development Association, Delhi

Financial Capacity

RATING - - CRISIL - 1 B

BANKERS - Industrial Development Bank of India (IDBI) Govt. of India Undertaking

Representations

+91- 7767 005 678

+91- 7767 005 678